|

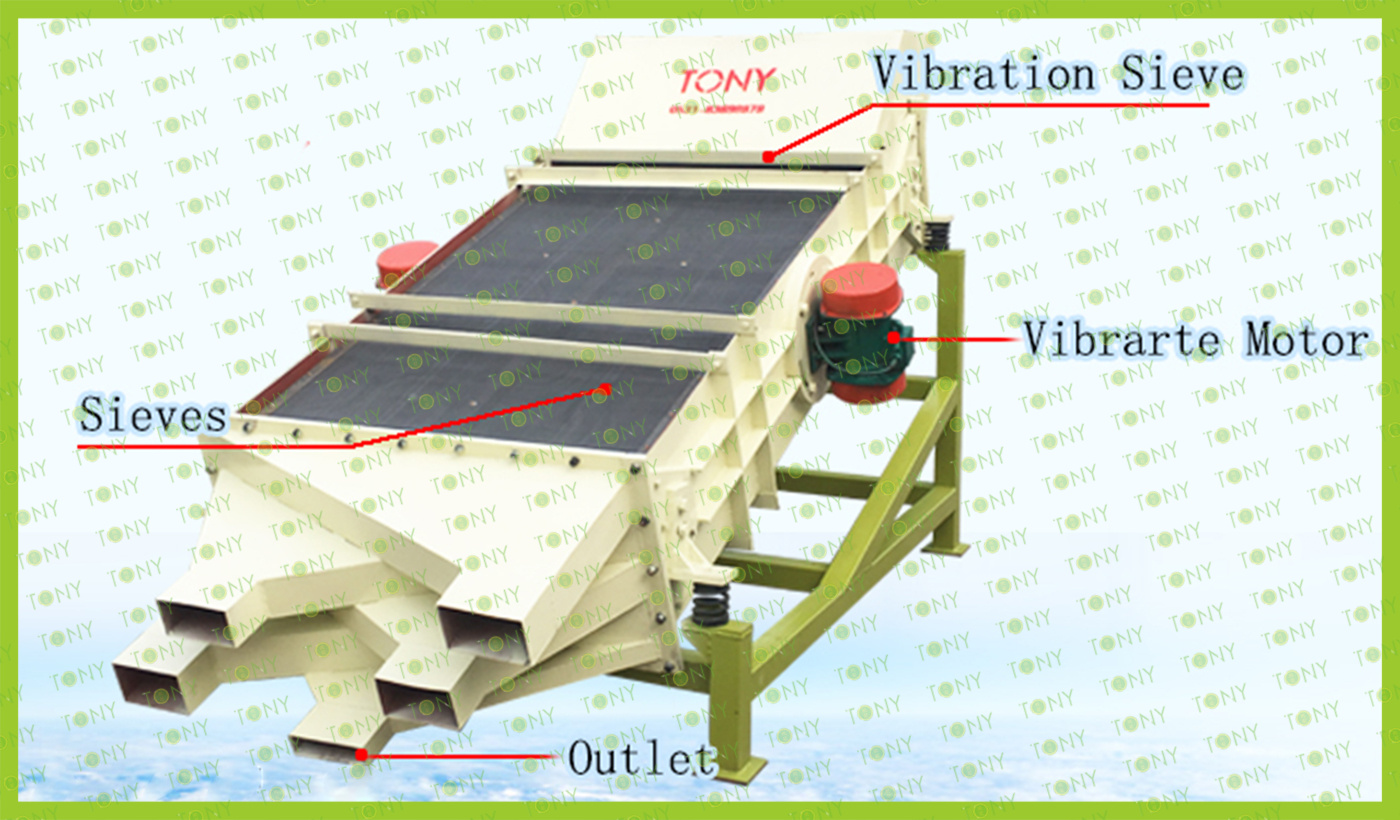

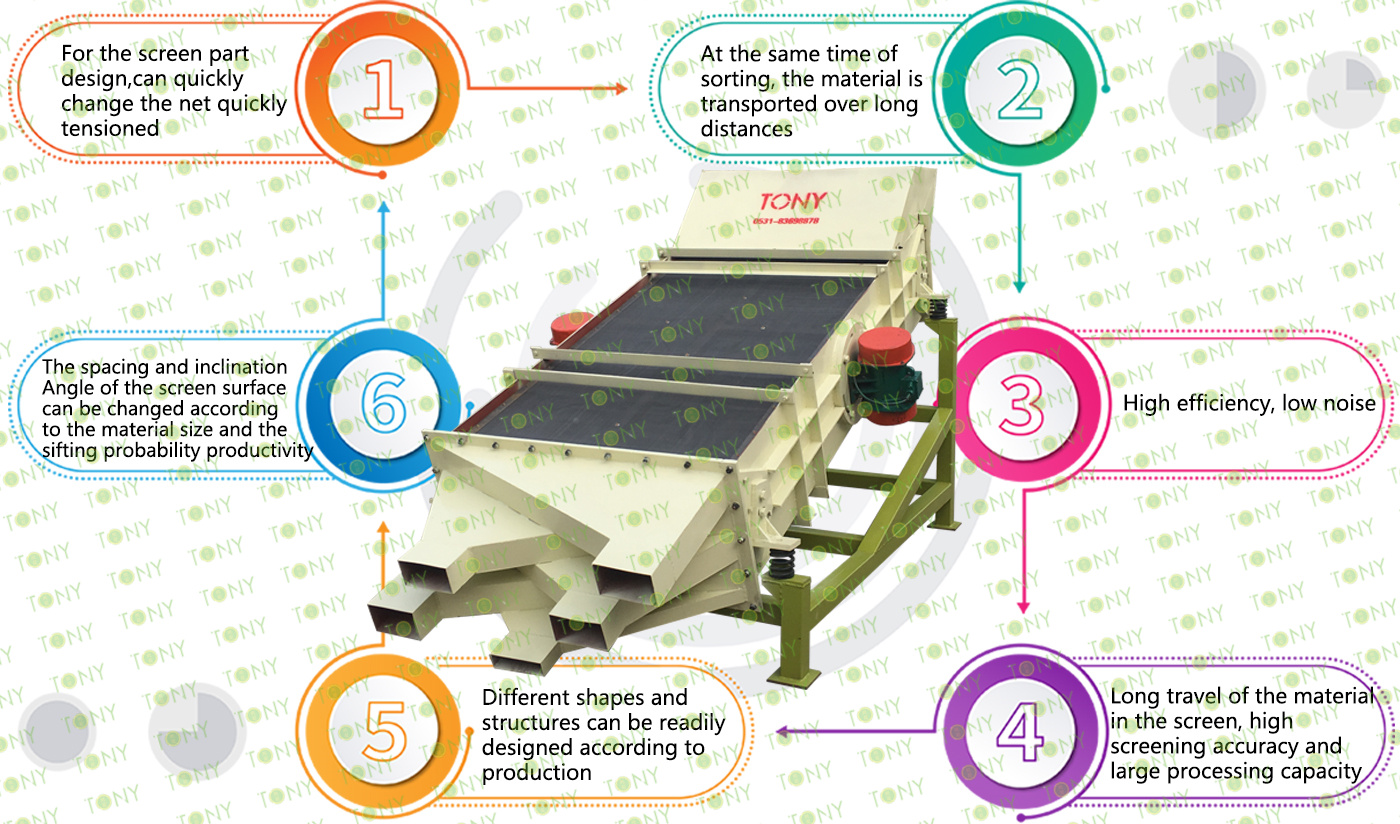

The TONY vibration classifier uses a horizontal vibration motor as the excitation source, throwing the raw materials onto the screen plate while simultaneously moving them forward in a straight line. The raw materials are evenly distributed via a conveyor into the classifier's feed port, where they pass through multiple layers of screen mesh to create meshes of varying sizes. Materials of varying sizes are discharged through their respective outlets. This classifier offers low energy consumption, high output, a simple structure, easy maintenance, a fully enclosed structure, and dust-free operation. The TONY vibration classifier is widely used in industries such as abrasive raw materials, chemicals, plastics, pharmaceuticals, resin powders, ceramic raw materials, metallurgy, building materials, grain, food, and fertilizers, grading various materials to varying degrees. It can be automated using assembly line operations. The market demand for vibration classifiers is stable, and through technological innovation and optimization, we are able to meet ever-changing market demands. |

|

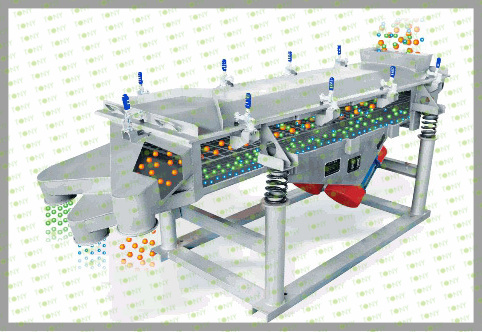

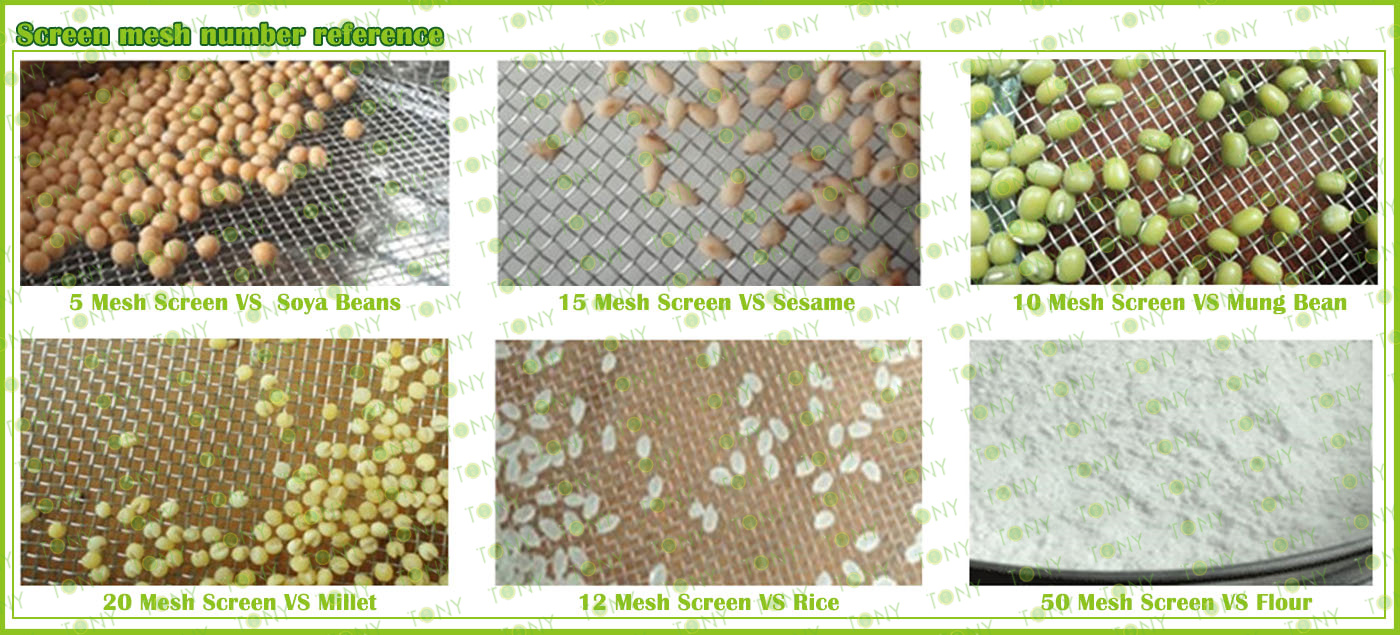

When a vibrating screen is operating, two motors rotate synchronously in opposite directions, generating a counter-excitation force in the vibrator. This forces the screen body and the mesh into longitudinal motion, periodically throwing the material on the screen surface forward under the action of the excitation force, thus completing the screening process. A linear vibrating screen is driven by two vibrating motors. When the two vibrating motors rotate synchronously in opposite directions, the excitation force generated by the eccentric masses cancels out each other in the direction parallel to the motor axis and adds to form a net force perpendicular to the axis, resulting in a straight line motion. The two motor shafts are tilted at an angle relative to the screen surface. The combined action of the excitation force and the weight of the material causes the material to be thrown onto the screen surface in a linear motion, thereby achieving the purpose of screening and grading. This type of screen is suitable for screening various dry powder materials with a particle size of 0.074-5mm, a moisture content of less than 70%, and non-sticky properties. The maximum feed size is no larger than 10mm. |

|

The product is widely used in chemical, food, plastics, medicine, metallurgy, glass, building materials, grain, fertilizer, abrasives, ceramics, coal, hydropower, mining and other industries .

|

TONY Vibration Classifier Type Model |

|||||

|

Model |

Power |

Capacity |

Violent Power |

Screening Area |

Weight |

|

TMZ60-2C |

0.25*2 |

1-2 |

3000 |

1000*600 |

0.8 |

|

TMZ80-2C |

0.25*2 |

2-4 |

5000 |

1500*800 |

1.1 |

|

TMZ100-2C |

0.37*2 |

3-6 |

6000 |

1500*1000 |

1.3 |

|

TMZ120-2C |

0.37*2 |

4-8 |

6000 |

1500*1200 |

1.4 |

|

TMZ150-2C |

0.55*2 |

5-9 |

8000 |

1800*1500 |

1.5 |

|

TMZ150-5C |

0.55*2 |

4-11 |

8000 |

1500*1200 |

1.6 |

|

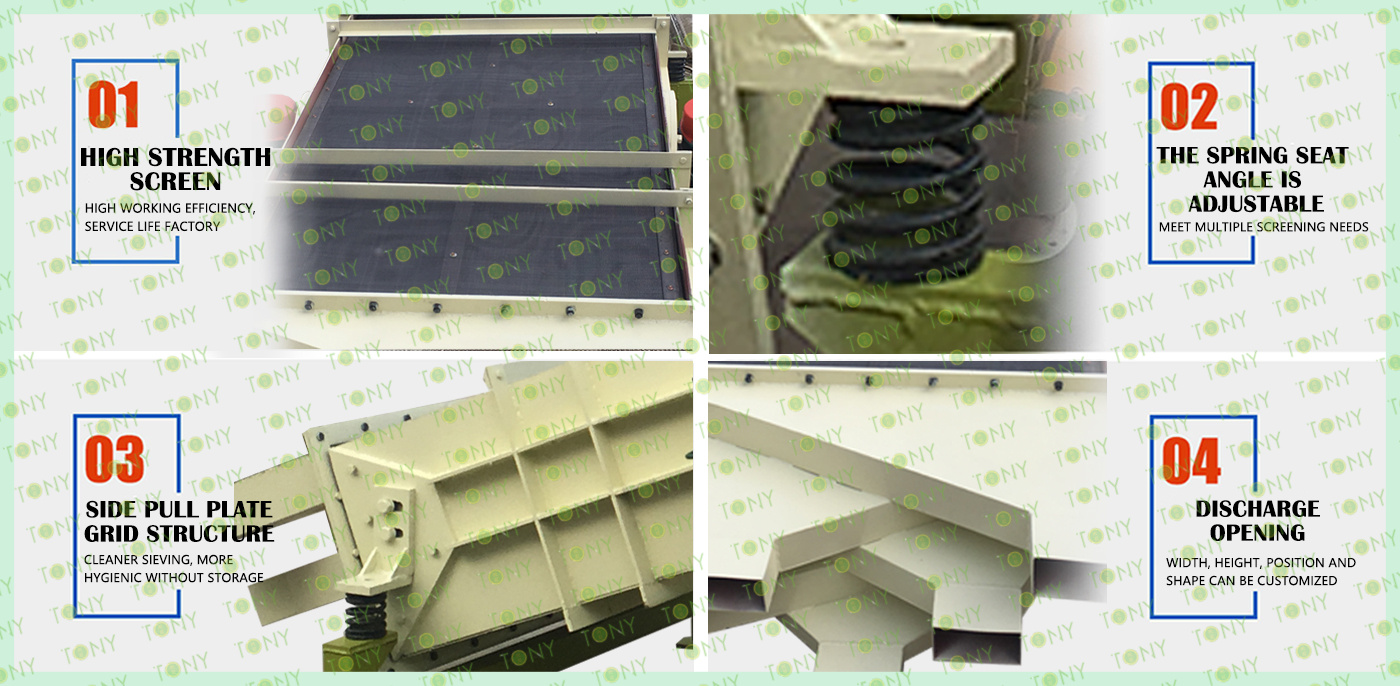

1. Efficient Screening: Due to the large acceleration of the material in the screen box, the screening efficiency is high, and the larger particles can be quickly separated; 2. Convenient Adjustment: The screening effect can be changed by adjusting the vibration force of the vibration device and the inclination of the screen box; 3. High Degree Of Automation: It is driven by an electric motor and does not require manual operation, which reduces labor intensity and working time; 4. Simple Structure: Since only a few parts such as the vibration device and the screen box are required, the structure is simple and easy to maintain and clean. 5. The Overall Stiffness Is Strong, Firm And Reliable: all parts of the screen body are welded by tying steel plates and profiles (part of the body is connected by water bolts) 6. Flexible Use: two vibrating motors can be installed with a layer or multiple layers of screen to do the excitation power supply, and the treatment effect is obvious 7. Wide Applicability: suitable for screening, classification, impurity removal, filtration |

The TONY TMZ series vibrating classifier is a high-precision, vibration-free screening and sorting equipment. Its screen layout and design vary depending on the material's screening requirements. Please select the appropriate model based on your material needs. If you are unsure of the specific model, please contact us.

Selection Considerations:

Length: Determines the material's travel time on the screen, affecting screening accuracy.

Width: Determines the amount of material that can pass through the screen in a single pass, affecting yield.

Material properties, such as viscosity and moisture content, require careful consideration when selecting the appropriate model.

Supporting Equipment:

Auxiliary equipment for the vibration classifier includes the screen, screen frame, rubber composite spring, vibration motor, motor base, damping spring, bracket, etc.

Price Range

The price of a vibration screen varies depending on the model and configuration. Please contact TONY for specific pricing.

1) Check the operation of the transmission mechanism.

2) Check whether the exciter temperature and gearbox oil level are normal.

3) Check whether the vibrating screen runs smoothly.

4) Check whether the connecting parts are firmly fastened.

5) Check whether the isolation spring and rubber shock absorber work normally.

6) Check whether the gear box vent is unblocked.

7) Check whether the material dispersion on the screening surface is uniform, whether the flow is smooth, and adjust if necessary.

8) Check whether the gap between the feed and discharge chute and the vibrating screen is moderate, and adjust it if necessary.

9) Check whether the screening surface is loose and whether the bolts in each part are tightened.

10) Check the bearing temperature of the transmission mechanism and whether there is abnormal noise.

11) Check the screen surface and other locations for material accumulation and blockage

|

The following services will be provided: 1.Raw material custom solutions. 2.Product details available within 24 hours. 3.The main departments control orders, strict quality inspection, standardized precision production. 4.Production and operation, send experienced staff to help customers produce. 5.24 hours telephone guidance and help customers train staff.Contact us and you will receive a professional response. We provide the best pre-sale, sale and after-sale service. We have a professional working team that can allocate the complete line for you, to ensure that you buy the best quality and fittest machine in least money. After sale, we provide one-year warranty to make sure that your machine runs functionally and consistently. We also provide lifelong services and spare parts for the machine. If you have any needs or suggestions, please feel free to contact us. |

If you are interested in a TONY vibrating classifier, please feel free to contact us.

1. Regarding pricing: Our equipment varies widely, and prices vary depending on the model.

2. Before receiving a quote, please clarify your raw materials, final product type, and production requirements.

3. After understanding your specific needs, we will match the appropriate equipment and provide a quote.

4. Price is only one factor in your purchase decision. We sincerely encourage you to visit us in person to learn more about us.

2025 Tony Machinery - All Rights Reserved. Map