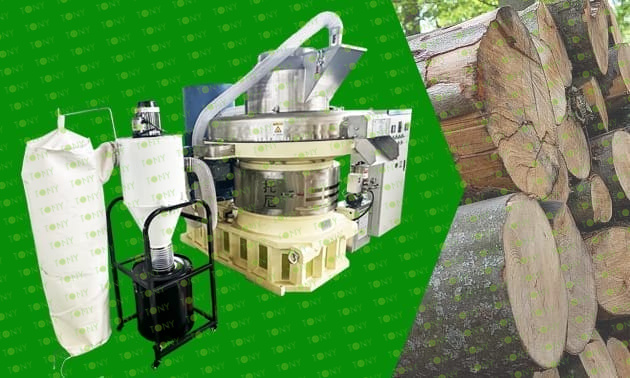

Biomass pellet machines, small devices that compress "loose waste" such as straw, wood chips, and agricultural and forestry waste into high-density pellet fuel (a single machine typically occupies only a few square meters, with investments ranging from tens to hundreds of thousands of yuan for small and medium-sized equipment), may seem insignificant, but with a "small incision" they are driving multi-dimensional environmental change. Their core value lies in transforming biomass waste from an "environmental burden" into a "clean energy carrier" through low-cost, localized resource conversion. Ultimately, this will create a significant "sand grains forming a tower" effect in areas such as pollution reduction and carbon reduction, resource recycling, and rural environmental protection.

1. Solving Waste Pollution: From Incineration and Landfill to Energy Utilization

Biomass waste, such as rural straw, logging residues, and fruit tree branches, has long faced environmental challenges. Open-air burning (in my country, annual straw burning once accounted for over 30% of total straw production) produces large amounts of PM2.5, CO₂, and toxic gases, contributing to autumn and winter smog. Indiscriminate stacking breeds mosquitoes and pollutes soil and water.

The biomass pellet machine uses "physical compression + low-temperature molding" technology to transform these waste materials into pellet fuel with a diameter of 6-10mm and a density of 1.1-1.3 tons/m³. The moisture content is reduced to 10%-15%, and the calorific value is increased to 4000-4500 kcal/kg, approaching that of coal. This process not only achieves "zero landfill and zero incineration" of waste but also creates clean energy. In rural areas, this "doorstep processing model" is particularly crucial: farmers collect straw and process it into pellets, which are directly used for heating their own villages and greenhouses. This not only reduces pollution but also reduces energy costs, creating a positive cycle of "environmental protection + economy."

2. The Big Advantage of "Small Equipment": Low barriers to entry promote environmental protection.

The miniaturization of biomass pellet machines is precisely their key to leveraging large-scale environmental protection:

Low investment threshold: Suitable for cooperatives, family farms, and even individual businesses, it is far lower than the entry threshold for biomass power plants (which can easily cost tens of millions of yuan), allowing environmental protection technology to reach the grassroots level.

Simple operation: Highly automated (one-button start, automatic loading, fault alarm), ordinary farmers can operate it after one or two days of training, addressing the problem of "technical talent shortage" in rural areas.

Flexible adaptability: Parameters can be adjusted according to the type of raw material (straw, wood chips, palm shells, etc.), adapting to the specific biomass resources in different regions (e.g., bamboo and wood are more common in the south, straw is more common in the north), achieving a "localized, customized" environmental protection solution. This "decentralized" environmental protection model no longer relies on "large projects and large investments" for environmental protection, but instead integrates the decentralized operation of countless "village-level particle points" and "township processing plants" into a nationwide environmental protection network.