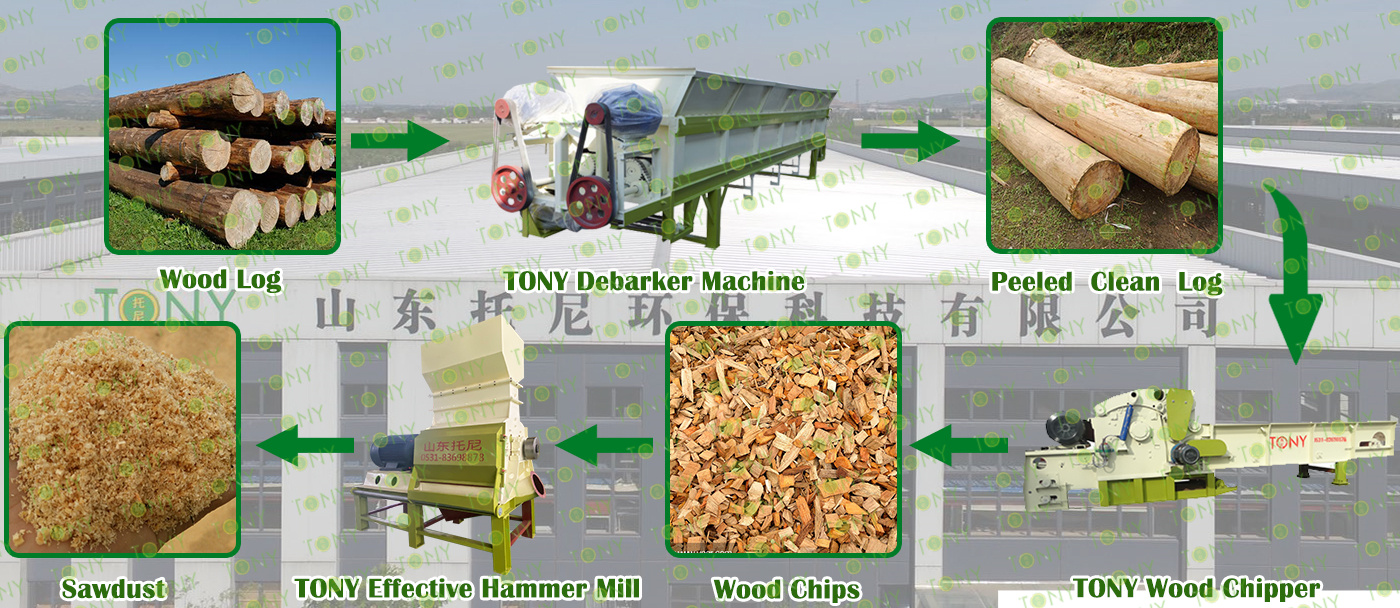

The role of wood debarker in the production of biomass pellets

Improve the quality of raw materials:

The bark usually contains more impurities, moisture and ash, which will affect the combustion efficiency and quality of biomass pellets. Removing the bark by a wood debarking machine can improve the purity of the raw materials, reduce the ash and moisture content, make the biomass pellets burn more fully, generate higher heat, and reduce pollutant emissions during the combustion process.

Protect subsequent equipment:

The existence of tree bark will increase the friction and wear during wood processing, cause great wear to subsequent equipment such as crushers and granulators, and reduce the service life and working efficiency of the equipment. Using a wood peeler to remove bark in advance can reduce equipment wear, reduce maintenance costs and equipment failure rates, and improve the stability and continuity of the entire production process.

Optimized pellet forming:

The wood after the bark is removed is easier to process during the crushing and granulation process, which can better control the size, shape and density of pellets, so that the biomass pellets are formed better, and the quality is more uniform, meeting the requirements of different users for the quality of biomass pellets.

TONY wood debarking machine has a high degree of automation, and the wood is rotated and peeled in the drum, which is simple and convenient to operate, can operate continuously, and has high production efficiency. At the same time, the shape and curvature of the wood are relatively low, and can handle many types of wood, which is suitable for the wood peeling process in large-scale biomass pellet production.