TONY biomass pellet fuel production line can optimize the drying molding process technology according to the characteristics of each biomass material, yield size, application requirements, cost control, degree of automation, field conditions, etc. It is suitable for processing wood chips, sawdust, bamboo chips, wood chips, shavings, corn straw, flax straw, wheat straw, cotton straw, straw, alfalfa grass, Miscanthus, peanut shell, rice husk, hazelnut shell, walnut shell and other materials.

There are many raw materials for processing biomass pellets, such as logs, pallets, templates, furniture waste, crop stalks, fruit hulls, branches and bark, sawdust and so on. A certain amount of raw materials should be stored before production so as not to delay normal production. At the same time, the raw materials stored should do a good job of safety: fire prevention and rain prevention.

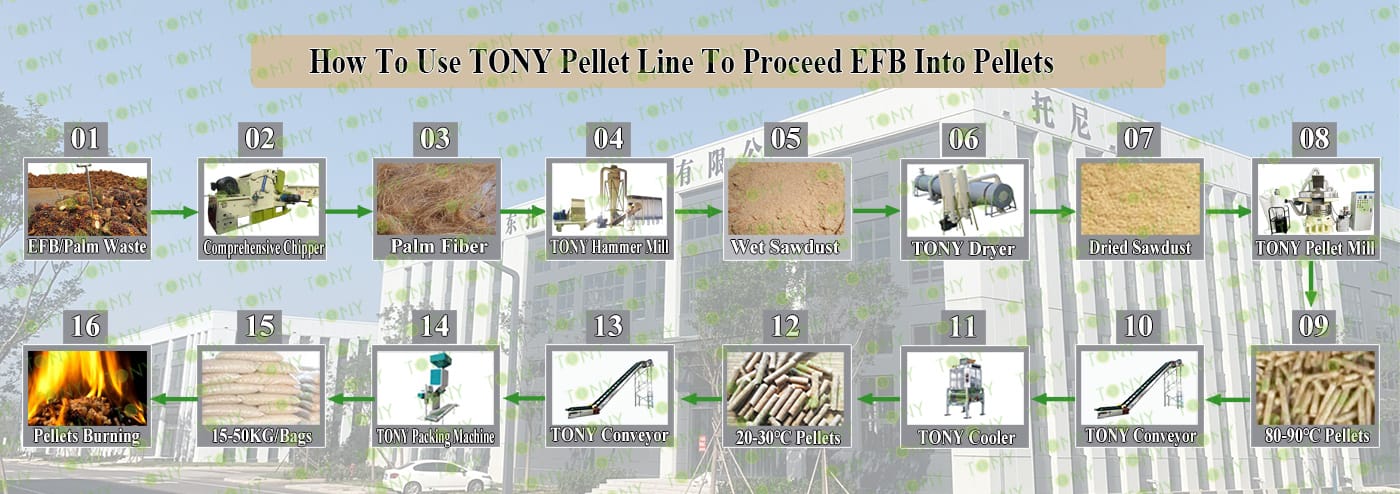

Biomass pellet machine complete equipment production process:

1. Crushing process: Take wood for example, first of all, break the logs into 25-55mm wood chips with a comprehensive chipper.

2. Fine Crushing process: The requirement for raw materials is sawdust, so the wood chips also need to be crushed. Depending on the specific situation, we can choose Effective Hammer mill or Multifunctional Hammer Mill , please consult TONY for details.

3. Drying process: The biomass pellet machine is very strict on the water content of raw materials, and the water is best below 15%. If the water is too much or too little, the resulting particles will crack or fail to form. If the raw material itself is dry, then this step is not necessary

4. Pelletizing process: biomass pellet machine is the most important equipment of the whole production line. According to the output and use, there are many types of pellet machine to choose from. Here we focus on the new 304 stainless steel vertical ring die pellet machine TYJ-551-132KW output can reach about 2-2.5 tons per hour, is a very popular pellet machine. The equipment has stable operation, strong pressure, large particle density, high molding rate and combustion resistance.

5. Cooling process: The temperature of the newly made biomass particles is as high as 80 or 90 degrees, and it needs to be cooled to room temperature by the cooling machine before it can be bagged and stored.

6. Packing process: the cooled particles are transported to the packaging machine by conveyor, the packaging machine is measured and bagged, and finally sent to the finished product warehouse. Then we can sell it directly.

In order to save effort, conveying equipment is usually configured in each section support. For example, it is used to transport wood chips, sawdust, particles, etc.

TONY customized production of complete sets of biomass pellet fuel production line, affordable, durable equipment high yield, environmental protection low consumption, high molding rate, stable performance, pellet fuel burn resistance, high heat.