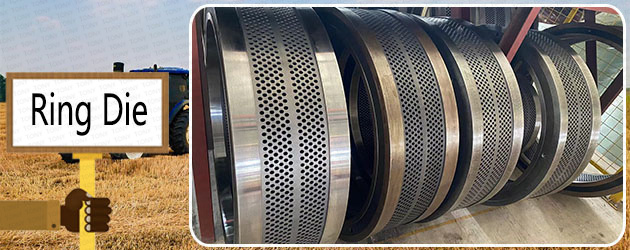

Extending the service life of the pellet machine ring die is the key to ensuring production efficiency and reducing costs. Here are some effective methods:

1. Choose a high quality ring die

Material selection: The selection of high-quality stainless steel material to manufacture ring die can improve its wear resistance and fatigue resistance.

Reasonable design: Reasonable ring die design can improve the performance of the whole machine and extend the service life.

2. Perform proper operation and maintenance

Adjust the gap: Adjust the gap between the ring die and the roller per shift, ensure that the gap is between 0.1-0.3mm, to avoid the eccentric roller contact ring die surface or one side of the gap is too large.

Avoid overload: When starting, the feed amount must be gradually increased from low speed to high speed to avoid damage to the ring die and pellet machine caused by sudden high speed operation.

Regular inspection: Check whether there are local protrusions on the inner surface of the ring die, and grind off the protrusions if necessary.

3. Daily maintenance

Cleaning and maintenance: After use, the residual raw materials are extruded to avoid the residue in the die hole drying and hardening.

Moisture-proof storage: The ring die should be stored in a dry and clean place to avoid corrosion caused by moisture.

Record usage: Record the usage of the ring die per shift in order to calculate its actual service life.

4. Preventive measures

Iron removal and impurity removal: Install iron suction device to prevent metal foreign matter from entering the granulation chamber and avoid ring die damage.

Regular replacement of wearing parts: timely replacement of worn parts, such as the drive wheel transmission key, hoop, wear-resistant bushing ring, etc., to ensure the normal operation of the pellet machine.

5. Professional customization

Customized ring die: According to different feed types and actual use, customize different processes of ring die to ensure its maximum use value.

Parameter selection: According to the chemical composition and physical properties of raw materials, select the appropriate ring die parameters, such as aperture, pass, length-diameter ratio, etc.

6. Troubleshoot the fault

Die hole plugging: such as die hole plugging, can be immersed in oil or oil after cooking granulation, if necessary, use an electric drill to drill out the blockage, and then use oily materials and fine sand for grinding and polishing.

Replace the ring die: When the centering pin or locking bolt of the ring die is broken, the die hole is not discharged, and the internal surface is seriously unequal, a new ring die should be replaced in time.

Through the above measures, the service life of the pellet machine ring die can be significantly extended, production efficiency can be improved, and production costs can be reduced.