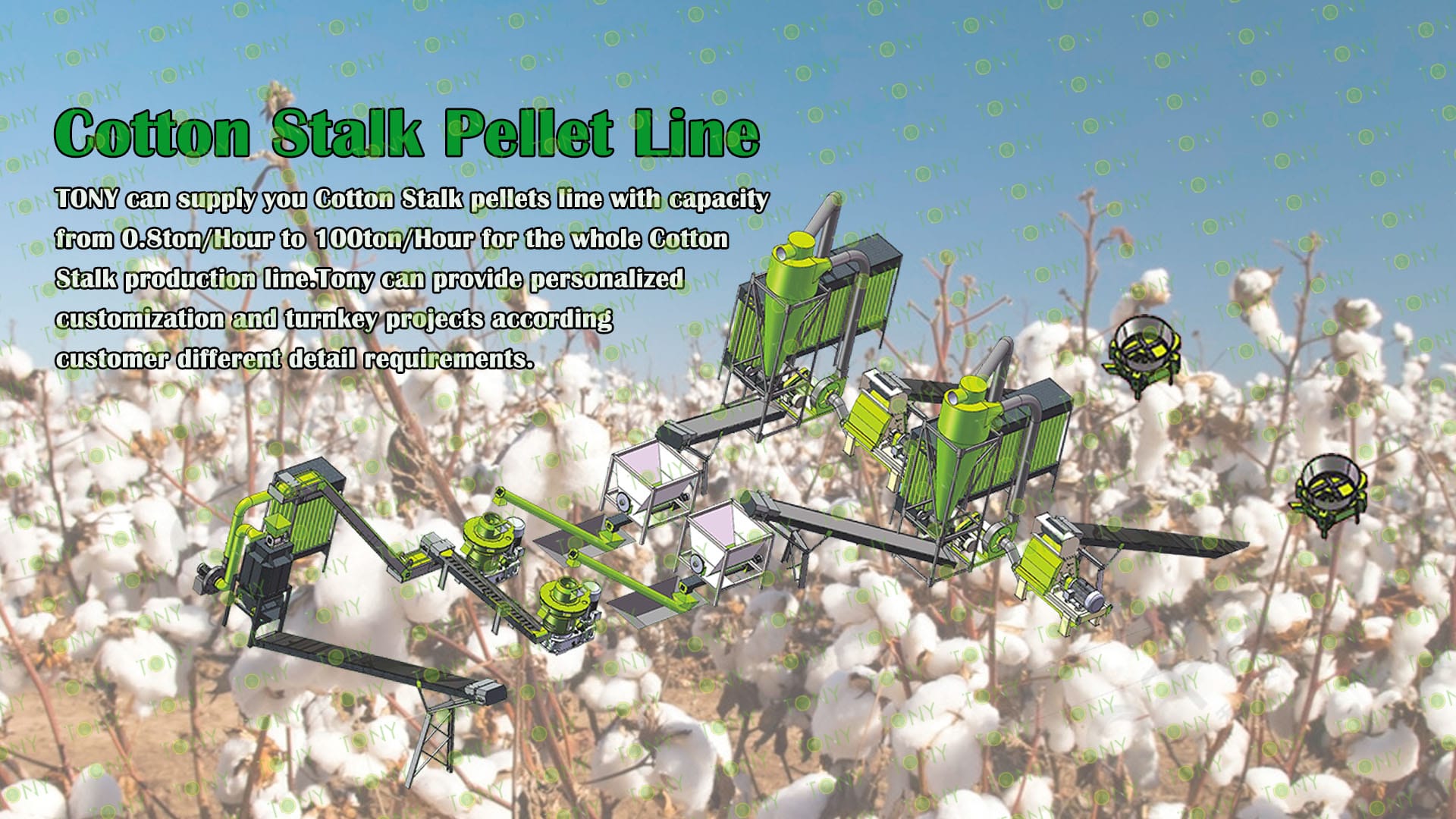

TONY Design 6-7Ton/Hour Cotton Stalk Production Line Specification

Overview of global cotton stalk resource distribution

1.Overview Of Global Cotton Stalk Resources

Cotton stalk is the residue of immature parts of crops and is an important agricultural by-product. cotton stalk can not only be used as animal feed and fertilizer, but also can be used in biomass energy, pulp and paper, biomedicine and other fields.

2.Distribution Of Cotton Stalk Resources

(1)Asia:Asia is one of the regions with the richest cotton stalk resources in the world, including China, India, Pakistan, Vietnam and so on. China is one of the countries with the most abundant cotton stalk resources in Asia, with an annual output of more than 2 billion tons of cotton stalk, most of which is used for the production of biomass energy and organic fertilizer.

(2)Europe:Europe is one of the regions with relatively rich cotton stalk resources in the world, including Russia, France, Germany, Poland and so on. Eu countries regard cotton stalk as a renewable energy source, and cotton stalk plays an important role in EU energy consumption.

(3)North America:North American countries, including the United States, Canada and Mexico, these countries are rich in cotton stalk resources, mainly used in power generation, production of paper, biodiesel and other fields.

(4)Africa:Africa is one of the regions where cotton stalk resources are relatively scarce, most of the cotton stalk is used as fuel, and a small amount is used for fertilizer and feed.

(5)South America:Resources in South American countries are relatively scarce, and cotton stalk is mainly used in the production of pulp and paper, animal feed and fertilizer.

(6)Australia:Australia's cotton stalk resources are relatively limited and are mainly used for the production of biomass fuels and fertilizers.

3.Conclusion

From a global perspective, cotton stalk resources are abundant in Asia, Europe and North America, while rare in South America, Africa and Australia. Among them, China is one of the countries with the largest output of cotton stalk. In the future, with the continuous enhancement of environmental awareness, the utilization value of cotton stalk resources will continue to be excavated.

Cotton Stalk Buning Has Many Disadvantages But No Benefits

The main reasons for banning cotton stalk burning include environmental pollution, health hazards, fire risks and traffic safety issues.

1.Environmental Pollution

Burning cotton stalk will produce a large number of soot, particulate matter and harmful gases, such as sulfur dioxide, nitrogen oxides and hydrocarbons, which will cause serious pollution to the atmospheric environment. Especially the newly harvested cotton stalk is not dry, incomplete combustion will produce a lot of nitrogen oxides, sulfur dioxide and hydrocarbons, and even under the action of sunlight will produce a secondary pollutant ozone . In addition, burning cotton stalk can also produce strong carcinogens dioxins, which pose a threat to human health .

2.Health Hazard

The smoke produced by burning cotton stalk contains a large number of nitrogen oxides, photochemical oxidants and suspended particles, which can irritate the mucous membranes of the eyes, nose and throat, causing cough, chest congestion and tears, and may lead to bronchitis . The impact is particularly severe for the elderly and children, as well as those with respiratory illnesses .

3.Fire Risk

Burning cotton stalk is very easy to ignite the flammable materials around, especially near the village, once it causes a fire, the consequences will be unimaginable. Sparks from the burning process could also start wheat field fires, resulting in economic losses .

4.Traffic Safety

Smoke from cotton stalk burning will reduce air visibility, affect road traffic and aviation safety, and easily cause traffic accidents . The effect is particularly pronounced on both sides of main traffic lines and near airports .

5.Soil Damage

Cotton stalk burning will destroy the soil structure, kill the beneficial microorganisms in the soil, affect the absorption of soil nutrients by crops, lead to the decline of farmland quality, and affect the yield and quality of crops .

To sum up, the prohibition of cotton stalk burning is to reduce environmental pollution, protect human health, prevent fires, ensure traffic safety and maintain soil structure.

1.First of all, cotton stalk pellets are widely used in the feed field.

Through microbial fermentation, cotton stalk can be made into highly nutritious feed, which not only increases the diversity of livestock feed, but also improves the nutritional value of feed. Experiments show that beef cattle fed with cotton stalk feed can gain more than 1.5 kg per day, effectively reducing the cost of breeding. In addition, cotton stalk feed technology has also helped farmers and herdsmen in southern Xinjiang to get rid of poverty and become rich through cattle and sheep breeding, alleviating the problem of lack of forage.

2.Secondly, cotton stalk pellets also have important applications in energy and materials.

Cotton stalk is mainly composed of cellulose, hemicellulose and lignin, which can be converted into high-value products such as bio-based materials, chemicals and biofuels. Although most cotton stalk is currently directly returned to the field or burned, resulting in resource waste and environmental pollution, the potential of cotton stalk will be further utilized through new ideas for high-value utilization.

3.Finally, the production of cotton stalk pellets is convenient and economical.

Using a cotton stalk pellet machine to make pellets is not only convenient and fast, but also low-cost, which is conducive to saving production costs and improving work efficiency. The produced pellets can be used to burn to generate electricity, and the gases emitted during combustion will not pollute the environment, making it a sustainable energy solution.

1.The main factors affecting the yield of cotton stalk pellets include raw material selection, raw material pretreatment, equipment configuration and ratio adjustment.

First of all, raw material selection is one of the key factors affecting the yield of cotton stalk pellets. The type and quality of raw materials directly affect the output and quality of pellets. For example, when cotton stalk is used as raw material, clean and impurity-free stalk needs to be selected to ensure the density and molding effect of the particles. In addition, the moisture content of the raw materials is also very important. Excessive moisture content will cause wall sticking during the granulation process and affect the output.

Secondly, raw material pretreatment is also an important factor affecting output. Impurities and moisture content in the raw materials will affect the molding effect and output of the particles. Through pre-treatment methods such as crushing and screening, impurities can be removed and the uniformity of raw materials can be improved, thereby increasing particle yield.

2.Equipment configuration is also an important aspect that affects output.

The design and automation level of biomass pellet equipment directly affect production efficiency and output. Reasonable equipment configuration and advanced process flow can significantly improve production efficiency and particle quality.

3.Finally, proportion adjustment is also a key factor affecting output.

During the production process, the ratio of raw materials needs to be continuously adjusted and optimized to ensure the best molding effect and output. For example, the proportions of raw materials such as Cotton Stalk chips and rice husks need to be adjusted according to specific conditions to achieve optimal yield and quality.

By optimizing raw material selection, pretreatment, equipment configuration and ratio adjustment, the yield and quality of cotton stalk pellets can be effectively improved.

The economic benefits ofcotton stalk pellets are very significant. cotton stalk is pressed into grains, as a biomass fuel, its benefits are mainly reflected in the following aspects,You can contact TONY for more details.

1.Economic Benefits

(1)Raw material cost estimation: The raw material of granular fuel is cotton stalk, which has a large amount of resources in rural areas, and was previously incinerated on the spot. If you have cotton stalk resources, then the raw material cost is basically 0, if you need to purchase cotton stalk as raw materials for biomass pellets, the cost price is also very low

(2)Other costs include fuel and power costs, wages and benefits, equipment depreciation, loan interest, etc., because many countries support the use of waste crop resources for biomass fuel, and the state also supports subsidies, so this part of the cost is also very low

(3)Select the cotton stalk pellet production line project to process cotton stalk into a certain size of granular fuel, with high calorific value, good strength, low pollutant content, stable performance and good economy.It's a good investment

2.Environmental Benefits

Improper disposal of cotton stalk will produce certain pollution to the environment. The cotton stalk is made into pellet fuel, which is burned by a special gasification boiler with a thermal efficiency of 81%, CO, S0, and close to zero emissions, which can replace non-renewable fuels such as coal and oil and reduce the impact of waste on the environment. By calculation, 1t granular fuel can reduce CO,1500kg, s0,25kg, and effectively improve the urban and rural air environment quality.

3.Social Benefits

The completion of cotton stalk biomass pellet fuel project can not only increase farmers' income, but also expand employment and reduce social unemployment. Secondly, the products can replace non-renewable energy, solve the energy crisis, and have certain social benefits for the establishment of a sustainable energy system and promote the development of the national economy.

The advantages of cotton stalk pellets are mainly reflected in the following aspects:

1.Resource Utilization:

Cotton stalk pellets are a kind of biomass pellet fuel with cotton stalkas the main raw material. Through pelletization processing, the resource utilization of agricultural wastes is realized, which helps to reduce environmental pollution and improve the efficiency of production. Economic value of cotton straw.

2.High Production Capacity:

The cotton stalk pellet machine has high production capacity, the production output can reach tons per hour, and the energy consumption is low. This gives cotton stalk pellets significant advantages in large-scale production.

3.High Nutritional Content:

Research shows that through granulation treatment, the nutritional content of cotton stalks retained and improved. For example, adding corn flour can increase the bulk density of the particles, reduce the powdering rate, improve digestibility and gossypol detoxification rate.

4.Wide Application:

Cotton stalk pellets can be widely used in domestic stoves, heating furnaces, hot water boilers, industrial boilers, biomass power plants, etc. It can replace traditional fuels such as fireCotton Stalk, raw coal, and liquefied gas, reducing usage costs and reducing environmental pollution.

5.Environmental Protection Features:

The waste gas emissions after burning cotton stalk pellet fuel are low, and the ash can be recycled as potassium fertilizer, realizing the recycling of resources and meeting the requirements of sustainable development.

To sum up, cotton stalk pellets not only have significant advantages in resource utilization and environmental protection, but also perform well in terms of production capacity, nutritional content and application range. They are a biomass fuel with broad prospects.

1.Current Market Demand For Cotton Stalk Pellet Fuel

At present, cotton stalk pellet fuel has not been popularized in most parts of my country. The main reasons are low market awareness, imbalance between supply and demand, and immature technology. However, with the country's policy advocacy and industrial support for green and environmentally friendly energy, the market demand for cotton stalk pellet fuel is gradually increasing. According to Zhilian data, the current market demand for cotton stalk pellet fuel has reached millions of tons, while the supply accounts for only about 2% of the national cotton stalk production, and the contradiction between market supply and demand is more prominent.

2.Analysis Of The Market Prospects For Cotton Stalk Pellet Fuel

As a renewable fuel, cotton stalk pellet fuel has broad market prospects. First, cotton stalk pellet fuel is in line with the country's policy orientation on environmentally friendly green energy, and the market demand prospects are broad. Secondly, cotton stalk pellet fuel is highly versatile and can be used for a variety of purposes such as home heating, industrial heating, and power machinery fuel, and the market space is huge. In addition, the production and transportation costs of cotton stalk pellet fuel are relatively low, and it has a large market price advantage. In addition, with the maturity of technology, the continuous improvement of production efficiency and output, the competitiveness of cotton stalk pellet fuel will continue to improve in the future.

In short, the market prospects of cotton stalk pellet fuel are broad, and its status will continue to improve with the development of China's economy and changes in the policy environment. At present, relevant industrial enterprises need to further strengthen technology research and development, improve product quality, improve the market supply chain, and ensure market prospects and production and sales market share.

1.Working Principle Of Cotton Stalk Biomass Pellet Processing Equipment

The working process of the equipment includes the following main steps:

(1)Feeding Stage: The raw materials enter the equipment through the feed port and are ready for the next step of processing.

(2)Preliminary Crushing: Before the raw materials enter the compression chamber, they usually need to undergo preliminary crushing to ensure that the raw material particles are uniform in size, which is convenient for subsequent high-pressure compression and molding.

(3)High-Pressure Compression: After the raw materials enter the compression chamber, they are subjected to strong compression force and are squeezed into strips or other shapes to enhance the bonding force between the particles.

(4)High-Temperature Treatment: The compressed raw materials enter the high-temperature furnace for heat treatment to promote the pyrolysis and polymerization of components such as lignin, and further improve the calorific value and corrosion resistance of the particles.

(5)Cooling And Molding: The raw materials after high-temperature treatment need to be cooled by the cooling system to prevent overheating, deformation or combustion, and then molded into regular granular solid fuels under the action of the mold or extrusion plate.

(6)Discharging Stage: The molded particles are discharged through the discharge port to become the final biomass pellet fuel product.

2.Characteristics Of Cotton Stalk Pellet Processing Equipment

(1)Cotton Stalk pellet processing equipment has the characteristics of high efficiency and low energy consumption. It can quickly process biomass raw materials into fuel pellets, which improves production efficiency.

(2)The pellet machine has molds of various specifications, and can select corresponding molds for processing according to different biomass raw materials, which improves the adaptability of processing.

(3)The equipment for processing biomass pellets has the characteristics of high automation and good safety, which effectively reduces labor intensity and improves production efficiency.

(4)The granular biomass fuel processed by the Cotton Stalk pellet processing equipment has stable quality and specifications, which meets the production standard requirements.

TONY Brand 6-7Ton/Hour Cotton Stalk pellet manufacturing plant can process cotton stalk,stlak,It is widely used in poultry feed, cattle, sheep and horse feed. It can also replace coal for burning.

1.Capacity: 6-7Ton/Hour

2.Raw materials: Wheat straw, corn straw, rice straw, beet straw, cotton straw,etc.

3.Moisture: About 10-15%.

4.Application: All kinds of stalk materials.

5.Finisheh pellets Markets:Feed, fertilizer and fuel fields

1.Project Name:Cotton Stalk Pellet Line

2.Raw Materisl:Cotton Stalk

3.Moisture Of Raw Material: 10%-15%

4.Capacity: 6-7Ton/Hour

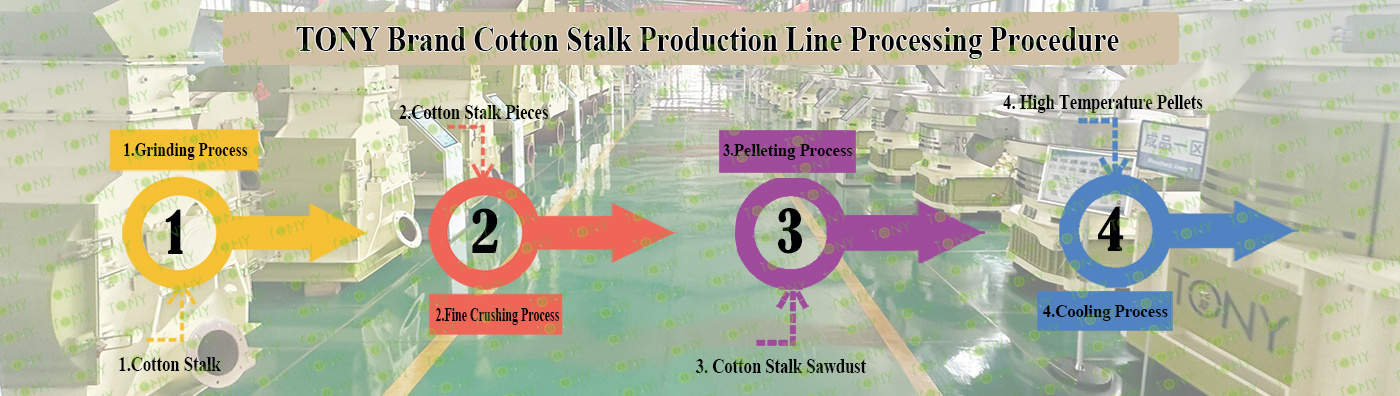

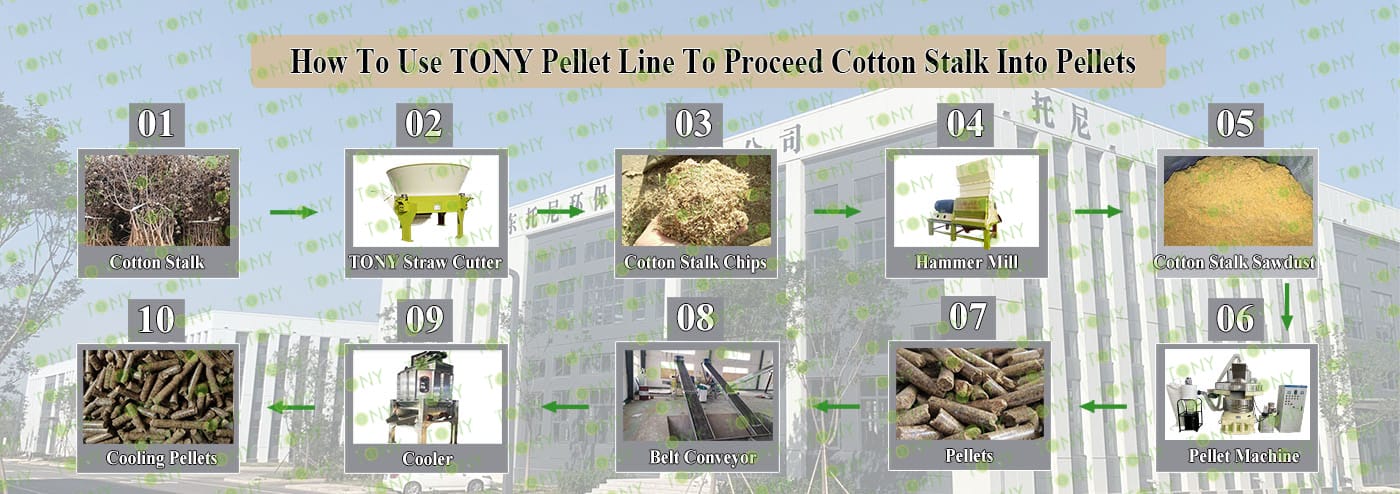

5.Process:1.Grinding Process→2.Fine Crushing Process→3.Pelleting Process→4.Cooling Process

6.Main Machine: Straw Cutter,Hammer Mill, TONY Pellet Machine TYJ860-III-220KW,Pellets Cooler,And Belt Conveyors.

7.Total Power: About 710KW

8.Need Area: About 600-700m㎡

9.Project Country: China

10.Voltage: 380V,50HZ

|

|

Project Layout For Customer |

|

1.Product: Cotton Stalk Pellets Line 2.Capacity: 6-7T/Hour 3.TONY Brand 6-7Ton/Hour Cotton Stalk Pellet Line Project Process 4.Main Machine:Straw Cutter,Hammer Mill, TONY Pellet MachineTYJ860-III-220KW,Pellets Cooler,And Belt Conveyors. 5.Total Power: About 710KW 6.Need Area: About 600-700m㎡ 7.Country: China |

|

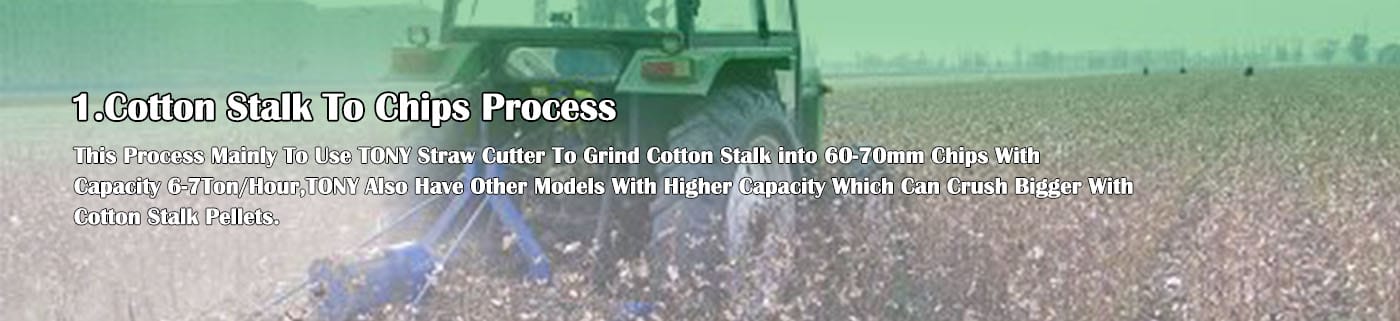

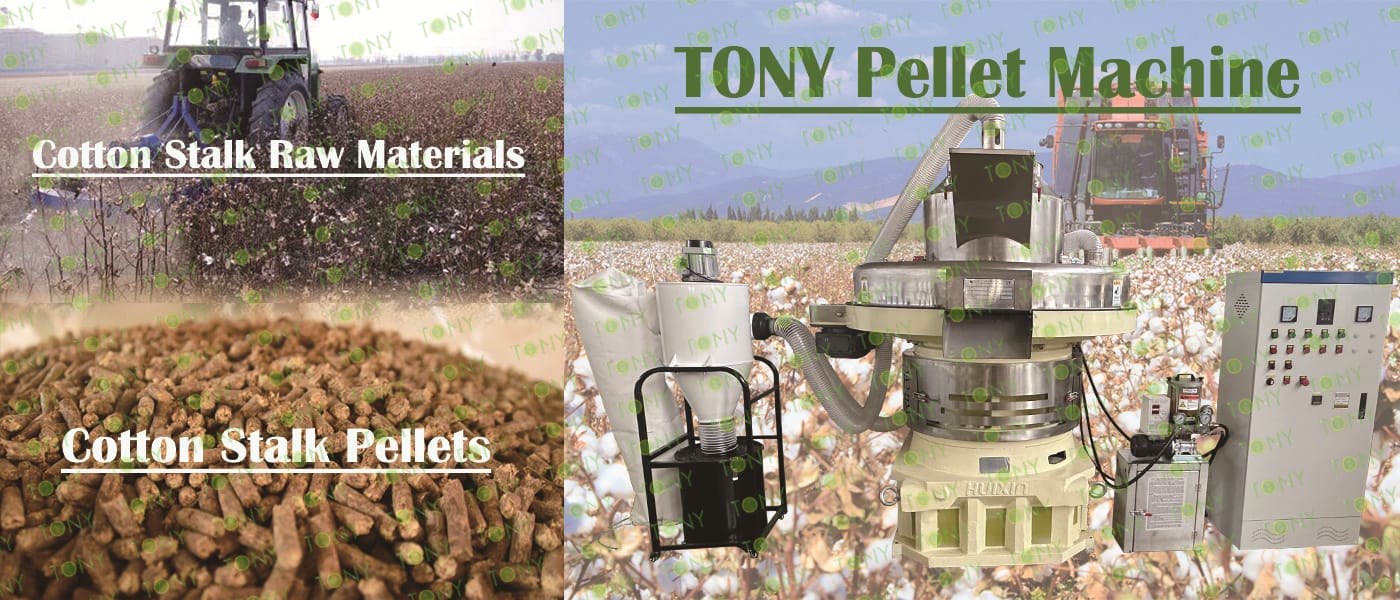

How to use TONY pellet line to proceed from Cotton Stalk into pellets? It mainly contains the following steps and machines as following: 1.To Use TONY Straw Cutter To Grind Cotton Stalk Into 60-70mm Chips. 2.To Use TONY Hammer Mill To Crush Cotton Stalk Chips Into 8-14mm Sawdust. 3.To Use TONY Vertical Ring Die Pellet Machine To Products Pellets With φ6-8mm. 4.To Use TONY Galvanized Cooler To Cool Pellets From 80-90℃ to 20-30℃. You can contact TONY to get for more details information and quotation. |

|

||||||||||||||||||||||||||||||||||||||||

Following TONY Will Introduce For You For All The Necessary Machinery That Will Be Used For The Whole Pellet Production Line. Some machines can be custom -made by customer according to different customer's detailed demand.Contact TONY for more details with quotation and layout.

|

|

|

|

| Straw Cutter | High Efficient Hammer Mill | Pellet Machine | Cooling Machine |

|

1.To Grind Cotton Stalk Bales Diameter ≤1.8 m Into 60-70mm Cotton Stalk Pieces 2.Model:TPX2000-90KW*2Sets 3.Capacity:3-4Ton/Hour/Set |

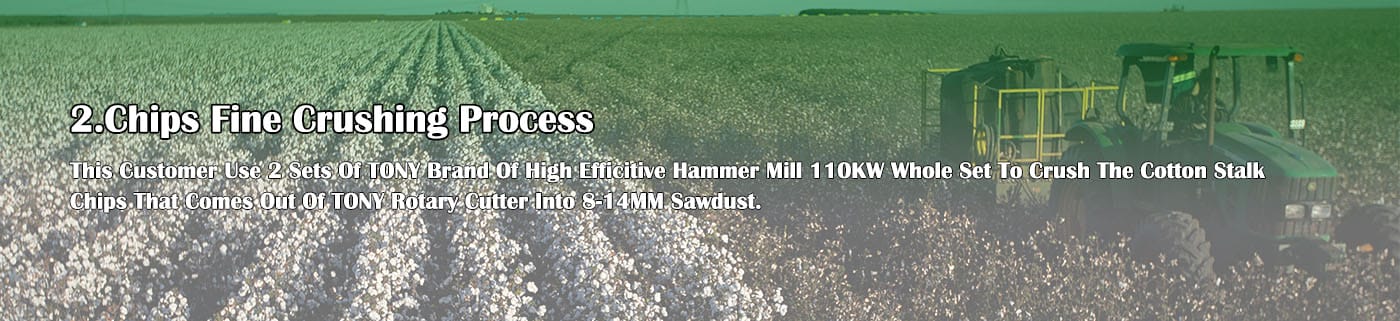

1.Crush 60-70mm Chips Into 8-14mm Sawdust. 2.Model: TFD75*100-110KW *2Sets 3.Capacity:3-4Ton/Hour/Set Total Capacity:6-7Ton/Hour |

1.Model: TYJ860-III-220KW*2Sets 2.Capacity:3-4Ton/Hour/Set 3.Total Capacity:6-7Ton/Hour |

1.To Cool Pellets From 80-90℃ to 20-30℃ 2.Model:TCN-4*1Set 3.Capacity:6-7Ton/Hour |

|

|

|

1.Grinding Process A.The process is mainly used to grind cotton stalk within 1.8m in diameter into dried straw pieces. The rotary cutting mode of the outer chain of the gear, the rotary cutting rotor blade is sharp, and the blade types are various, which can be rotated to cut various bales of straw with different diameters, different thicknesses, different lengths and different water contents B.TONY brand straw cutter TPX2000-90kw models *2set C.Capacity:3-4Ton/Hour/Set Main Parts: (1)Tony's New Straw Cutter (2)Enlarged Turntable (3)Rotary Cutting System (4)Drive system (5)Electrical Cabinet. |

|

|

|

|

2.Cotton Stalk Chips Fine Crushing Process: A. This process is mainly used to crush 60-70mm cotton stalk chips into 8-14mm sawdust. B. Capacity:6-7Ton/Hour. C. TONY use high effective hammer mill TFD75*100-110KW-2Sets for this process. Main Parts: (1)TONY High Effective Hammer Mill. (2)90Holes Galvanized Dust Collector. (3)Sawdust Transportation Fan Blower. (4)Cyclone With Airlock. (5)Electrical Cabinets. |

|

|

|

|

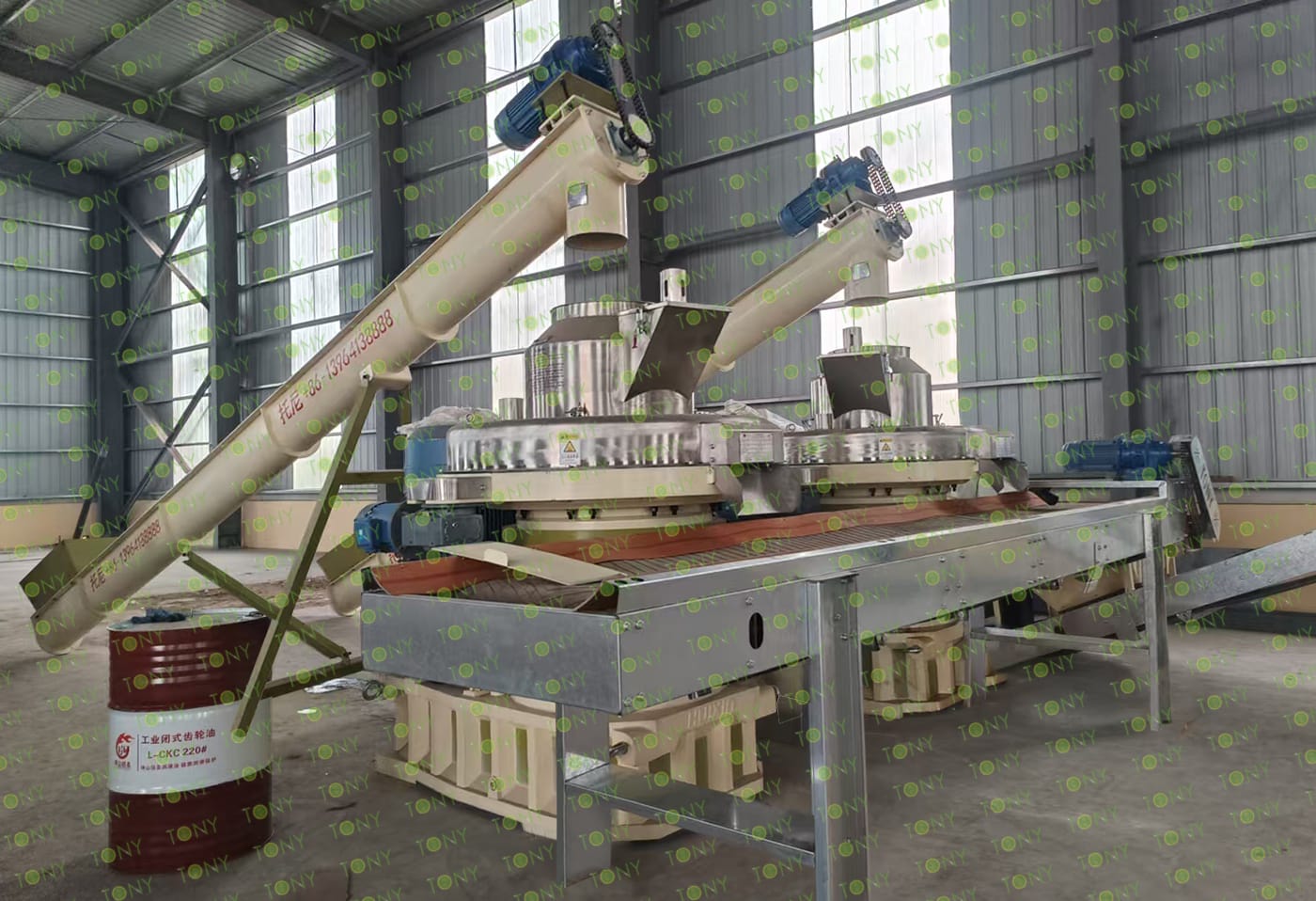

3.Pelleting Process: A.This process is mainly used to to product pellets with φ6-8mm. B.Capacity:6-7Ton/Hour. C.The Customer chose 2 sets of TONY brand Vertical Ring Die Pellet Machine TYJ860-III-220KW with capacity 3-4Ton/Hour. Main Parts: (1)TONY's new vertical ring die pellet machine. (2)Cyclone and bags dust collectors. (3)Bearings automatic lubrication system. (4)Electrical cabinets. You can choose TONY new type SS304 pellet machine or old type MS pellet machine. |

|

|

|

4.Cooling Process: A. This process is mainly used to to cool pellets from 80-90℃ to 20-30℃ B. The customer chose 1set of TONY Galvanized Cooler Separator with capacity 6-7Ton/Hour. Main Parts: (1)TONY's new Galvanized Cooler Separator With Vibrating Screen. (2)Cyclone and bags dust collectors. (3)Fan Blower. (4)Connect Pipes. |

TONY Detailed Design 3D Layout With Detailed Size For 6-7Ton/Hour Cotton Stalk Pellet Line According To Cusomer Factor Size

1.With the increasing energy and environmental crisis, biomass energy has been paid more and more attention as a renewable and clean energy. Taking cotton stalk as an example, the deep exploitation potential is very great. Biomass utilization can be divided into many kinds, and processing biomass into compressed pellet fuel is an advanced biomass utilization way. The content of S in biomass pellet fuel is less than 1/10 of coal, and its replacement of coal combustion can effectively reduce the emission of SO2 in the atmosphere, and the ash generated after combustion is an excellent natural fertilizer. At present, biomass pellet gasification combustion is a clean and environmentally friendly combustion mode, which is of great significance to reduce pollution emissions and protect the atmospheric environment.

2.As a very important agricultural resource in agricultural production, cotton stalk is very common in rural areas and the amount is very huge, there has been no good treatment method, if the on-site incineration, then it will cause pollution to the environment, and choose cotton stalk as raw materials for biomass particles, there is a very low raw material cost. If there is a large amount of wheat resources in or around it, it is equivalent to zero raw material costs.

3.Biomass fuel is not only environmentally friendly but also provides a choice for the country's energy needs. The market demand for biomass fuel is increasing, and the price of biomass pellet energy made of cotton stalk is also steadily increasing. For entrepreneurial projects, there is a very considerable profit margin. Therefore, the use of cotton stalk to produce biomass pellets is multiple. In addition to protecting the environment and helping to solve employment problems, there are considerable economic and energy sustainability.

Advantages of cotton stalk as biomass pellet fuel:

The combustion performance of biomasspellet s is not only reflected in environmental protection and economy, as well as the impact on social development and the improvement of energy structure, but also has its own unique combustion performance advantages, which are mainly reflected in the following points:

1.The calorific value and ash content after combustion of biomass pellet fuel are about 10% lower than that of medium coal. However, biomass pellet fuel burns out in the working situation, while coal can not burn out, and the cinder remains 10% to 15% of the combustible composition. Therefore, the calorific value of the two is comparable in actual use.

2.The ignition property of biomass pellet fuel is better than that of coal, and it is easy to ignite, which greatly reduces the ignition time.

3.The solid emission of biomass pellet fuel is lower than that of coal, which reduces the cost of discharging slag and environmental pollution. The solid emission of biomass pellet fuel is all ash, accounting for about 0.4%~7.0% of the total weight; The solid emissions from coal combustion are a mixture of ash, alkali and residual coal, about 25% to 40% of the total weight.

4.The degree of air pollution and boiler corrosion of coal is much greater than that of biomass pellet fuel. Soot contains a large number of granular C and toxic SO2, CO and other corrosive gases. The main component of biomass pellet fuel is C-H organic matter, there is no granular C and SO2 gas in the flue gas, mainly C-H volatile gas, and its SO2 and CO emissions are close to zero. When burned, the smoke color is less than Ringelmann 1, which will greatly reduce air pollution and carbon dioxide emissions, and biomass pellet fuel is known as a "clean fuel" in the international reputation.

5.The cost and time of using biomass pellet fuel for boiler fuel is less than that of burning coal. A 0.5t boiler burning biomass pellet fuel costs 11% less than burning coal, saving 34% of time, a 0.5t boiler fuel costs relative to coal reduced 10%, saving 16% of time.

6.The continuous combustion time of general biomass pellet fuel is 8 to 10 times higher than that of soft bulk material, and it is in a stable and continuous combustion state.

Crop straw pellet fuel technology belongs to the field of biomass energy application, without adding any additives, cotton stalk, corn straw, cotton stalk, soybean stalk and other crop straw into pellet fuel, with high density, high molding rate, high caloric value, clean and clean, no pollution, convenient storage and transportation and many other advantages. The product can not only be used as fuel for special boilers, heating furnaces, fireplaces, etc., but also as feed for livestock.

1.Current Situation Of Cotton Stalk Pellet Fuel Market Demand Pellet Fuel Market Demand

Current market demand:

(1)Production Growth: Biomass pellet production has continued to grow in recent years, and with the advancement of technology and the expansion of market demand, production is expected to further increase.

(2)Technological Development: biomass pellet production technology continues to improve, including raw material pretreatment, molding process, drying technology, etc.

(3)Market Application: Biomass particles are widely used in heating, power generation, industrial boilers and other fields, and the market demand continues to expand.

(4)Policy Promotion: The state has introduced a series of policies and measures to encourage the development and utilization of biomass energy, including tax incentives, financial subsidies and so on.

(5)Standard Formulation: Relevant departments have formulated quality standards and production specifications for biomass pellets to ensure product quality and the healthy development of the industry.

With the increase in global demand for renewable energy and the concern to reduce greenhouse gas emissions, biomass energy as a clean energy alternative to fossil fuels, has been rapidly developed, and many countries are actively promoting the development and utilization of biomass energy.

2.Analysis Of Pellet Fuel Market Prospects Of Cotton Stalk

With the development of economy and the improvement of people's living standards, the demand for energy is growing. As a renewable energy source, the market demand for biomass pellets continues to expand. With the rapid development of the industry, the upstream and downstream industry chain of biomass particles has gradually improved, including raw material supply, production and processing, logistics distribution, marketing and other links, forming a relatively complete industrial system.

Biomass particles are not only used for power generation and heating, but also widely used in industrial production, agricultural breeding, domestic energy and other fields, and the expansion of the application scope has further promoted the development of the industry.

The biomass pellet industry has shown a good development trend under the promotion of policy support, market demand, technological progress and other factors. In the future, with the further implementation of relevant policies and the continued growth of market demand, the biomass pellet industry is expected to achieve more rapid development.

2025 Tony Machinery - All Rights Reserved. Map