As a key device for converting agricultural and forestry waste into clean biomass energy, Biomass pellet machines play an indispensable role in national energy development and utilization. Their importance is mainly reflected in the following aspects:

1. Promoting energy structure transformation:

They replace fossil energy sources. Biomass pellets are made from raw materials such as crop residues, forestry waste (such as wood chips and bark), and livestock manure through compression and shaping. When burned, their carbon emissions are close to "carbon neutrality" (the carbon dioxide absorbed by plant growth is basically balanced with the carbon dioxide released during combustion), effectively replacing coal, natural gas, and other fossil energy sources, and reducing greenhouse gas emissions.

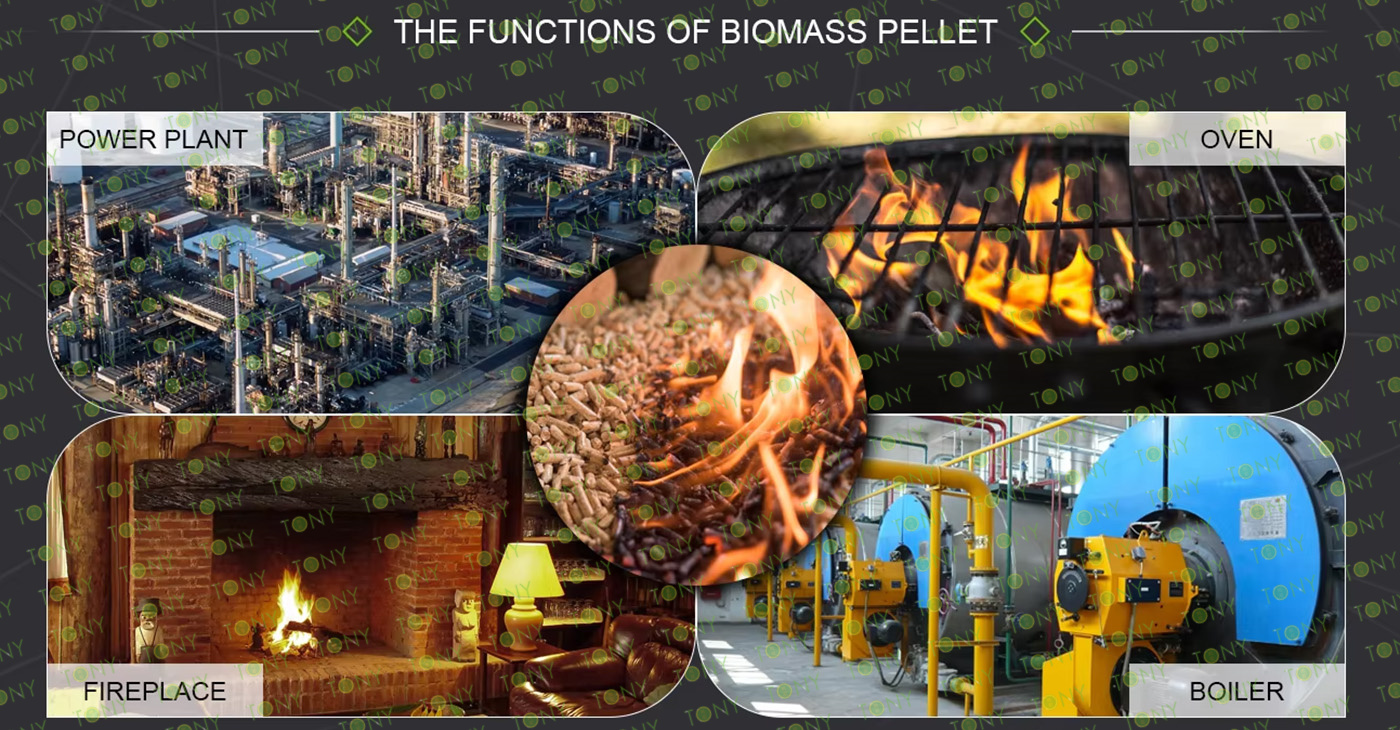

Suitable for energy demand scenarios: Biomass pellets have stable combustion and high calorific value (usually 4000-5000 kcal/kg), and can be widely used in industrial boilers, residential heating, power generation, and other fields. For example, in small thermal power plants, biomass pellets can be mixed with coal for combustion or used as fuel for power generation, reducing reliance on traditional fossil energy.

2. Promoting the resource utilization of agricultural and forestry waste

Solving waste treatment problems: Every year, several hundred million tons of agricultural and forestry waste are produced. Traditional treatment methods (such as incineration and landfill) not only waste resources but also cause environmental pollution (such as haze caused by open-air burning of straw). Biomass pellet machine convert these wastes into high-value energy products, achieving "turning waste into treasure".

Driving the extension of the agricultural industrial chain: Biomass pellet production can form a "raw material collection - processing - sales - application" industrial chain, providing job opportunities (such as raw material acquisition, pellet processing, etc.) and increasing income.

3. Ensuring energy security and optimizing the energy supply structure

Enhancing energy self-sufficiency: Biomass energy is a domestic renewable energy source, with wide sources and recyclable regeneration, reducing dependence on imported fossil energy and lowering the impact of international energy price fluctuations on energy security.

Supplementing the energy supply system: In the energy consumption structure, biomass pellets, as an important component of distributed energy, can make up for the shortage of centralized energy supply.

4. Mature technology and broad application prospects

Improvement of equipment performance: Modern biomass pellet machines adopt extrusion molding technology, compressing raw materials into pellets through ring molds or flat molds, featuring high molding rate (up to 95% or more), low energy consumption, and high automation. Some equipment can also adjust parameters according to the characteristics of raw materials to adapt to different materials (such as moisture-laden straw or hard wood chips).

In summary, the biomass pellet machine, through technological innovation, transforms scattered agricultural and forestry waste into standardized energy products. It plays a crucial role in energy conservation and emission reduction, resource recycling, and energy security. It is an indispensable important equipment in the national energy development and utilization, and has far-reaching significance for building a clean, low-carbon, safe and efficient energy system.